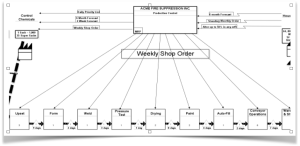

Perhaps one of the least well understood or appreciated parts of the Value Stream Map is the information flow at the top. That said, it’s an important part of the entire flow of a value stream. There is much to be learned from it. Let’s examine.

COMPANY (Production Control) BLOCK: Let’s start at the Company block, top center. Here we note the Name of the company being studied. If there are multiple value streams in this company, you may also list the value stream’s name. In our case, the company’s name is Acme Fire Suppression, Inc. Also here we’ll indicate who is at the Hub of the Information flow: Acme’s Production Control office. It’s rare that production control does not control the flow of production-related information.

Finally we note whether our processes are all manually scheduled or computer scheduled, and what type of scheduling tool is bing used. In our case, processes are being controlled by a Material Requirements Planning (MRP) software program. That bit of information alone tells us volumes.

COMMUNICATION FROM CUSTOMER: Recalling that, by convention, the Customer is always on the top right of the VSM, we see that Acme’s customer is providing them with three separate forecasts. First, there is six month forecast of their needs.

This forecast is “squishy,” in that it only gives us a guess of what our customer really intends to buy. Sales can use this forecast and we can develop an estimated Takt Time from it, but we really shouldn’t spend money or commit resources based on this forecast. The reason for that recommendation will become evident when you see the monthly order.

The semi-annual order is a little more firm, but still nothing you can sink make long-term plans around. Even the monthly order represents a target value. Implied in this order is the hope that this order quantity will stay the same from month to month; however, the contract with the customer has provisions in it that allows them to alter this standing order, up or down, by as much as 50% in any month.

If you think about it, that’s a lot of potential fluctuation. Only when the final, amended, order arrives can we really schedule the month’s production. The amended order alone gives us “actionable” information.

COMMUNICATION TO SUPPLIERS: Now let’s look at what Acme communicates to its Suppliers. Again, by convention, supplier information is found on the top left side of the VSM.

Like their own customer, Acme gives their suppliers as much of a view of the future as they can; so, they send suppliers a six month forecast. As I said earlier, this is just a guess for planning purposes, but nothing the supplier can hang their hat on.

Next, Acme sends suppliers a two week forecast. This is getting firmer, meaning that Acme knows they’ll be close to actually buying these quantities. Then comes the weekly shop order that gives suppliers specific quantities to produce and ship. Finally comes the daily priority list that gives Acme the ability to tell suppliers the order in which they want materials made that day.

One might well ask why the daily list when there are only two shipments a week, but this is Acme’s way of projecting consumption by their own factory.

Seem confusing? At least it’s all documented! From a well-documented process you can make corrections that will improve it.

This VSM is likely the only place in a company where all this information exists in a single place. Think about the implications of that. If no one has been looking at all this, on what have decisions been based?

In the absence of such cross-functional communication many organizations fall into silo behavior, where everyone does their own thing, ignoring its implications on the rest of the organization. By contrast, imagine if all departments worked from a single sheet of music that was updated on a timely basis.

INTERNAL COMMUNICATION: We have one more flow to follow, and that’s the flow within Acme. This one is easy. The VSM shows us that once a week, the MRP systems sends (“pushes”) shop orders to each operation in the value stream. Each shop order is an order to “build,” instructing that operation in what they are to make, in what quantity, in what order and when it’s needed.

One thing common to all communication in this Current State map: it all is pushed. There is no feedback loop or any sense of give and take to the flow of information. Especially in the factory.

Keep in mind: When every operation is being scheduled, even though some operate at very different cycle times, MRP-generated schedules almost always lead to products being “Pushed” and a lot of WIP (read: excess inventory).

I’ll end the discussion of the information flow here, but can you start to see how densely the VSM is packed with information? As I said earlier, this is information rarely found in a single place anywhere else in an organization. Once you’ve made the effort to document it, you’ll want to keep the VSM accurate by updating any changes.

Next, we’ll examine the flow of raw material and finished goods.