Q. How do you keep the pace of an assembly operation constant?

A. Big businesses use conveyors, or some other piece of big mechanical equipment, that conveys Work In Process (WIP) at a constant pace. If you’re not in a big business, you may think that you can’t afford such a luxury. Hope is not lost.

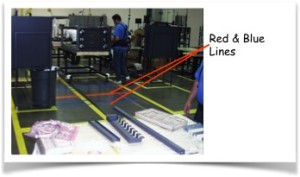

I ran across a very inexpensive way to control assembly line speed. It’s called the PACER CORD. See top photo.

Here’s the way it works. The pacer cord is drawn by a winch. The outside diameter (OD) of the capstan (motor-driven spindle or drum) is sized so that it pulls the cord at a specific speed. What speed? Takt Time!

|

| Photo #1 |

In the 2nd photo there are a series of horizontal blue lines and a single red line. These lines correspond to the operational steps in the two Standard Work Combination Sheets (SCWSs). Note the SWCSs visible in the first photo.

|

| Photo #2 |

The red line indicates a break point: a changeover, from one operator’s SWCS to the next. That red line means that operator #1 must be finished by that point, and that operator #2 must begin.

The blue lines in the 2nd photo correspond with the time of each operational step in the SWCSs. These lines allow the operators to glance at the floor while working. They are looking to see if they are ahead or behind pace. If they fall behind, they know they need to catch up.

A missed handoff at the red line will mean that the Cycle Time (CT) will be greater than Takt Time (TT). That’s a very bad thing. Do you remember why? I discussed it in my post on Takt Time. If you’re not sure, it’s a good time to refresh.