A lot of Americans bridle at the use of Japanese terms to describe Lean things. I feel very much the opposite. Language springs from cultures and shared experiences. So, when I use a Japanese word, it’s because it describes something that isn’t the same as terms we recognize. Obeya (Oh-Bay-Ah) is such a term. We think we know what it means, but do we? Let’s check.

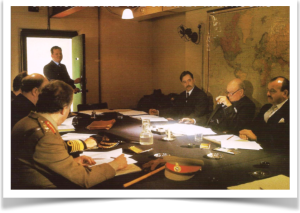

Most in the Western world are familiar with the “War Room” concept. Originally, it was a tent and later a room. It was rimmed with maps and bulletins about the enemy. It was a place where allies gathered to plan strategy and tactics against their common enemy.

The War Room concept was later modified for business and became a room where those planning (and often executing) a project gathered to share updates. Walls were covered with graphs, drawings and Gantt Charts, and participants were welcome to wander in and out between scheduled updates.

Much like the War Room, the Asian Obeya or “Large Room” is a place for members of a team to gather, but there are some significant distinctions.

- Occupancy: The “Large Room” (Obeya) isn’t just a place to meet. In addition to meeting there, team members usually occupy the Large Room full-time. This becomes where they work.

- Cross-Functional: The team of occupants usually represent all the disciplines involved in the execution of a project. To give you a sense of its use, the Obeya is used by companies like Toyota for the design and execution of a new car. From concept to launch, members from all the disciplines involved move into the Large Room and take up residence.

- One Team: Team members are encouraged to think of themselves as a single team. While the details of what goes on within the Big Room may not be shared outside it; within it, everyone is encouraged to see their teammates as part of one large team.

- Wall Adornments: Like a war room, the walls of the Large Room are covered with charts and reports, but far more. It’s typical for disciplines within the larger team to have their own wall space. They frequently meet at their part of the wall and discuss their own tactics, advances made, and problems encountered. Later, the same sub-team charts will be used to brief the larger team, not just the leaders: everyone.

- Surfacing Problem: The surfacing of problems is welcomed at all times, but especially in the Large Room process. With some Japanese companies, problems not only don’t get swept under the rug, everyone is encouraged to surface them. In this frame of thinking, the identification of a problem leads to its solution. The solution leads to advances, and often breakthroughs. Hence, bringing a problem to light is seen as a very good thing.

- Collaboration: Team members are encouraged to collaborate with members of other teams within the Large Room. This often solves problems much faster than conventional stovepipe management, and speeds the entire process. This collaboration is the primary reason for moving all the players into the Large Room.

I’ve posted about Kaikaku in the past. Different from Kaizen, with it’s narrow focus and tight time frame, a Kaikaku tackles an entire system at once. Because of the huge scope, a Kaikaku takes weeks, and often months, to complete. They are usually selected because they frequently lead to industry breakthroughs and may be part of the Hoshin Kanri process.

The Large Room Management style is frequently used to facilitate the Kaikaku process.