Toyota Principle # 7 – Use Visual Control So No Problems Are Hidden

Toyota Principle # 7 – Use Visual Control So No Problems Are Hidden

For those of you who haven’t been exposed to the VISUAL nature of lean, here are some thoughts as to why it’s so important.

DISCIPLINE – Lean requires discipline. I can’t repeat that often enough. Making things visual is just one of the disciplines of Lean.

In every job (not just those where you make your money), ask: “How would this look to someone who doesn’t know what’s going on?”

LAYOUT – Think about how you do your job, and what tools and materials are required. Then rearrange your desk, bench or floor so that your tools are where you need them (no more than an arm’s length). Same with raw materials.

LAYOUT – Think about how you do your job, and what tools and materials are required. Then rearrange your desk, bench or floor so that your tools are where you need them (no more than an arm’s length). Same with raw materials.

ORDER – Arrange your tools & materials in a logical order; e.g. by size, weight or order of use. Position them so they are not only easy to see, but feel.

Feel? Absolutely. My sensei used to layout benches so that the worker could select the correct tool by feel. When he finished, workers could sweep the back of their hand along the row of tools and count. When their hand reached the correct tool (say the 3rd), they grabbed it. Meanwhile, their eyes never left the work.

He laid hardware out the same way. If the worker was right handed, tools were placed on the right and the hardware on the left. Workers could soon garb the correct screwdriver and screw simultaneously, without ever looking.

VISUAL SWEEP – A key to good visual control is what Boeing calls the “visual sweep.” Create layouts in which you can sweep your eyes across a work area and know if something is out of place or missing.

VISUAL SWEEP – A key to good visual control is what Boeing calls the “visual sweep.” Create layouts in which you can sweep your eyes across a work area and know if something is out of place or missing.

Visually sweep every work cycle: Complete the work cycle; Visually sweep; Restore the work area to original condition; Start the next work cycle.

SIGNS – Consider whole buildings. Is it clear where things are? Can a customer easily find what they need in your store? In your offices?

How about in your hospital? Can visitors find your Lab, radiology, cafeteria, consultation rooms and doctor’s offices?

Within a cubicle farm, could a visitor find the media center (printer/copier, etc.)?

STANDARD PLACE – If you assign things homes and make those homes obvious (visible), you can train people to return things to their standard place. Once disciplined, employees will stop the time-wasting practice of hunting.

Don’t limit these practices to factories. Consider offices. Do the large hole punch or paper cutter have a standard place? Are filing cabinets and reference books located close to those who use them? Is their location visible and clear?

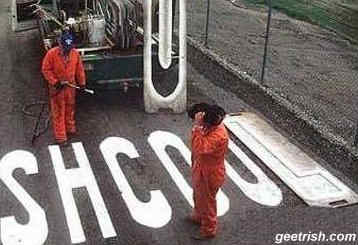

COLOR – How can color make problems evident? Color-code tools so you can tell from its color where it belongs. Use color on floors, too. Consider painting (or taping) colored outlines to locate Standard WIP carts for various departments.

I once worked with a factory that used color-coded WIP pallets as Kanbans. The color indicated to which cell the pallet was to be returned once filled.

LABELS – Are outlines self-evident, or are they labeled? Can you tell from an outline whether you’re missing a Phillips-head or flat-tip screwdriver? Can you tell where to locate a 10” vs. 8” crescent wrench?

VISUAL INSPECTION & POKA-YOKE – Think of an egg carton. If an egg is missing, you can tell immediately. Poka-Yoke, roughly translated as “mistake-proofing,” works the same way. Make it difficult, if not impossible, to make a mistake.

I worked with a metal fabricator whose plater sometimes lost parts. That meant the fabricator ended up being short on their own shipments.

To prevent that, the fabricator created carts that held the exact number of parts they needed each day. If one was missing, it was evident and the plater would go back to dredge their tanks until they found the missing part.

In short, strive constantly to make RIGHT and WRONG, GOOD and BAD visually apparent.