Remember, a Value Stream Map should be communicating to you and to your organization. So far we’ve examined how the flow chart and data boxes communicate. Now we’re going to examine how the supply and delivery icons communicate.

On the top left are the supply icons. They tell us who the major suppliers are. In the case of Acme Fire Suppression, Inc., the two major suppliers supply the steel blanks for use in the Upset operation and the chemicals used in the Auto Fill operation.

We know from my earlier description of the process that there are other supplies used in the process, e.g. the paint, the inert gas, the spray nozzles, cardboard overpack and boxes. None of those made it onto this VSM. The reason is mostly because they’re commodities, and easily available. We just want to look at the high $ items, or the items that could potentially shut us down if they weren’t delivered in a timely fashion.

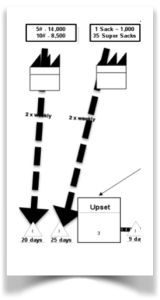

So, looking at the steel blanks, what do we see? Well, at the top we see that we’re getting two different types of blanks: the 5 pound and the 10 pound. We can see they come from the same supplier (normally the name of the supplier would be in the factory symbol). Finally, we can see that we get shipments of 14,000, 5# blanks and 8,500, 10# blanks.

Next we see that the steel blank supplier delivers twice a week. And, we see that we keep a 20 day inventory of their blanks at all times. One should logically ask why we’d inventory 20 days worth of these blanks when they have the potential to deliver twice weekly. Good question.

Next let’s look at the chemical supplier. They are shipping 35 super sacks of the chemicals a month (each super sack weighs 1,000 pounds). The same chemical is used in both the 5# & 10# extinguishers. Meanwhile, Acme keeps a 25 day inventory of the chemical.

Next let’s look at the chemical supplier. They are shipping 35 super sacks of the chemicals a month (each super sack weighs 1,000 pounds). The same chemical is used in both the 5# & 10# extinguishers. Meanwhile, Acme keeps a 25 day inventory of the chemical. Now let’s look at the delivery side of the VSM. From this diagram we see that Acme ships out of their warehouse once a month. Each shipment contains 40,000 5# extinguishers and 24,000 10 # extinguishers.

Again, this is all just data at this point, but it’s also something we call Actionable Information. By that we mean that we have enough information to actually make decisions and formulate action plans.

Case in point: why would Acme only ship once a month and keep a 30-day inventory of fire extinguishers? Doesn’t that violate at least one of the 7 wastes? Armed with that information, what actions might that lead Acme to make?