It’s been so long sin ce I used a “push” system, I wonder sometimes if anyone still does. Then I realize how shallow the penetration of Lean has been into the manufacturing world, much less the non-manufacturing world. Of course people still use “push!”

ce I used a “push” system, I wonder sometimes if anyone still does. Then I realize how shallow the penetration of Lean has been into the manufacturing world, much less the non-manufacturing world. Of course people still use “push!”

So, perhaps a brief explanation.

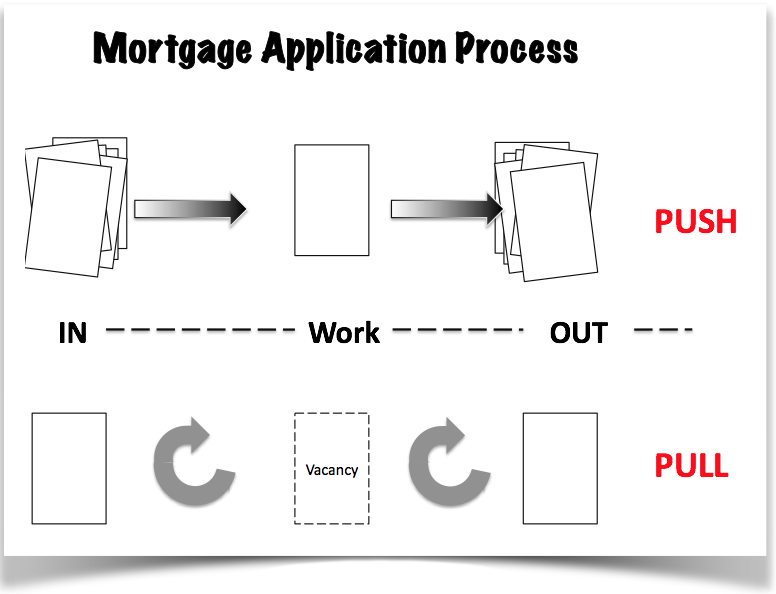

PUSH occurs when a process is allowed to “ship at will.” That means, as soon as workers finish their contribution, they are free to “ship” to the next operation.

What might this look like? Well, let’s say you process mortgage applications. If your’s is like most organizations, your IN basket is always full, whether with paper applications, or electronic. That’s a “push” system. As soon as a new application arrives, it goes immediately into your in box.

What might this look like? Well, let’s say you process mortgage applications. If your’s is like most organizations, your IN basket is always full, whether with paper applications, or electronic. That’s a “push” system. As soon as a new application arrives, it goes immediately into your in box.

PULL, on the other hand, requires the receiving process to create a vacancy for a new piece of work.

Picture the same process. As the processor completes one application, and puts it in their OUT box, the vacancy on their desk (or screen) signals they’re ready for the next. That vacancy “pulls” the next application.

This “vacancy” might work electronically, placing a new application on their screen; or, it might be that they have to physically pick up the next application as they drop off the previous. However it works, a “pull” system meters the number of applications in the process.

Now, let’s go back and look at that OVERPRODUCTION issue.

The waste of OVERPRODUCTION becomes very easy to spot. OVERPRODUCTION presents as mountains of Work In Process (WIP). In an office, that produces full IN boxes, and sometimes, full OUT boxes. In a factory, it’s even more visible.

In either case, OVERPRODUCTION becomes INVENTORY. INVENTORY needs to be stored in physical space. That space needs to be secure, almost always dry and in conditioned air. That space costs money to build, maintain, secure and keep conditioned. By the way, that’s true of computer servers, too.

Moreover, INVENTORY has to be maintained: counted, dispensed, received and cared for. All of those activities are part of your costs. Imagine if you didn’t have them. You could sell your products for less (grow market share); or, put more to your bottom line (increase profit).

Let me give you one more incentive to “pull:” Improved Cash Flow.

Organizations that “pull” move faster from beginning to end. The faster they deliver their end product, the faster they get paid. That would psyche the heads of the organizations I know.

So, if you’re still “pushing,” what will it take to get you to “pull?” Why not find out? Let’s talk.